INFRASTRUCTURE

Dye Unit at Rugs Hub

At Rugs Hub, we take pride in operating our own state-of-the-art dyeing plant to achieve exceptional results tailored to our specific yarn color requirements by customers.

Key Features of Our Dyeing Plant:

Yarn Varieties: Specialized in dyeing cotton yarn, Wool, cotton chenille yarn, viscose, jute/hemp, and seagrass (natural yarn).

Capacity: Capable of dyeing approximately 2,000 to 2,500 kilograms of yarn per day, ensuring high-volume production while maintaining quality.

Advanced Equipment: Modern dyeing machines for precision and consistency in colors across all yarn types.

Commitment to Sustainability: We uphold a policy of creating a safe and healthful workplace, protecting the environment, and conserving energy and natural resources.

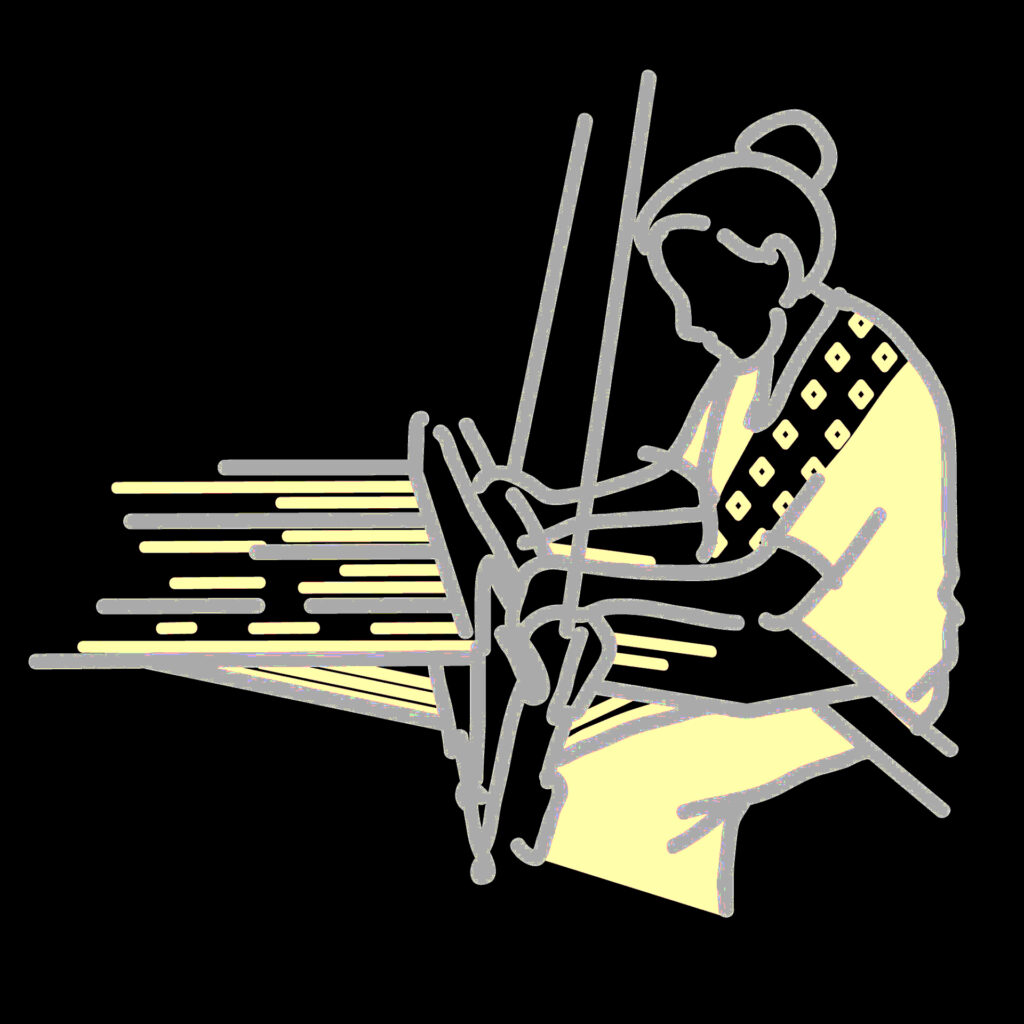

Weaving Unit

At Rugs Hub, our in-house weaving center spans a vast area, thoughtfully divided into various units for efficient operations. Each unit is dedicated to the art of creating exceptional rugs, crafted by our highly skilled and creative local weavers.

Our production center specializes in a variety of weaving styles, including:

- Flat Weaving

- Shaggy Textures

- Cut-Shuttle Designs

- Loop Patterns

- Designer Weaving

- Jacquarch Weaving

These techniques reflect our commitment to innovation and tradition, ensuring top-notch quality in every rug we produce.

Inspection, Finishing & Packaging

At Rugs Hub, the finishing and inspection of our rugs are meticulously carried out by our skilled artisans under the supervision of experienced staff.

Our packaging process adheres to the highest quality standards. We prioritize moisture-proof packaging with proper labeling to ensure safety and ease of handling, maintaining the integrity of our rugs during transit.